Jupiter Hydro Inc.

Energy That Doesn’t Cost The Earth.

Jupiter Hydro Inc. is a private Canadian company that has developed a patented in-stream hydrokinetic power generation system which is simple, robust and more cost effective than any of the competition. The company was founded by CEO Ross Sinclaire in 2010 after he observed the failure of the OpenHydro technology in the Bay of Fundy. He felt that the OpenHydro technology was too complicated and that bladed technologies such as those used in wind turbines were simply not the way to go either because water is 800 times more dense than air and, in his mind, the physics was all wrong. To back up this statement, one only needs to be aware of the fact that after spending over $700M, OpenHydro went out of business because they could not make their turbine work. Companies like GE and Voith have spent huge amounts as well and abandoned efforts to make bladed wind type turbines work in the ocean. In 2023, SME Canada went into voluntary bankruptcy because they were unable to prove that they do not harm fish species at risk. Other bladed technologies are also on hold due to this same issue. On June 16th, 2023, The Department of Oceans and Fisheries (DFO) made a ruling that, in their view, the Jupiter Hydro technology does not harm the fish. THIS IS A HUGE BREAKTHROUGH FOR JUPITER as it means that Jupiter will be able to proceed with our 2 MW project in the Minas Channel in the Bay of Fundy which will bring in over $40M and we will also have the opportunity to go into other berths in the FORCE Site in the Minas Channel. This will make Jupiter Hydro very profitable right here in Nova Scotia and enhance its ability to roll out this simple, cost effective and robust technology worldwide.

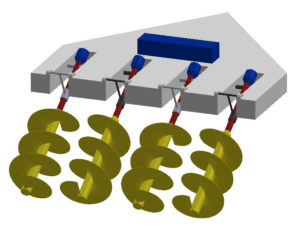

When Ross Sinclaire, Founder & CEO of Jupiter Hydro first started, he ended up experimenting with the 2500 year old Archimedes screw as an alternative solution to bladed turbines. This experimentation has been very fruitful and has led to where Jupiter Hydro has very strong patents in 24 countries. These patents are based on the optimal angle of the screw to the flow and the optimal pitch of the flights. See “Technology” and “Technology Advantages” to understand more about this unique concept.

DESIGN/BUILD PHILOSOPHY OF THE JUPITER FOUNDER

Because Ross Sinclaire has been designing and building mechanical systems all his life, this is the process he fully intends to stay with as Jupiter begins its commercialization phase. That is why he has chosen to work with a highly qualified design builder like Greg Farrow and a pioneer in large 3D printing like Jeff and Max from Loci Robotics. The final pieces of the puzzle have only come together in the spring of 2023 and, until they were in place, Ross has been reluctant to promote or raise more funds to make it happen. See “About Us” to read about Greg, Jeff and Max as well as Ismael.

With this team in place and our manufacturing facility secured, we will build and deploy our simple and robust technology in the Bay of Fundy and it will work. We are less than 1/3rd the cost of our main competition and, as such, the Jupiter technology is poised to dominate the tidal energy business worldwide.

TEN ADVANTAGES OF THE JUPITER TECHNOLOGY OVER COMPETING TECHNOLOGIES AS PRESENTED BY WORLD CLASS EXPERT RAY HUNTER WHOSE PICTURE IS AT THE BOTTOM OF THIS PAGE:

1) The Jupiter technology is less costly because it is mounted on a simple barge which is far less costly to build than units with lots of curved contours.

2) Far easier and less costly to maintain because most of the maintenance is done on the platform and accessed with a small service boat.

3) The turbine is more efficient because it starts generating power at very slow flow rates.

4) It is more robust and able to handle the turbulent water flows because the energy that is transferred into rotational torque is spread over the entire area of the turbine.

5) Because of the angle of orientation to the water flow, the bearings are far less stressed than conventional bladed turbines.

6) It has a single anchor point with a solid swing arm that protects the power cable from the turbine down to the ocean floor.

7) The only moving part that is in the water is the screw turbine itself.

8) The turbine platform weathervanes in the tidal flow and, therefore, there is always an unrestricted energy exchange from the flowing water to the screw turbine. In other words, it is just as efficient in both directions of flowing water.

9) Because the screw turbines extend out of the back end of the platform, it naturally aligns with the flow and is efficient throughout the tidal cycle despite having wind and waves from the side at times.

10) The 3D printed screw could last for 20 years without any issues.

The unit shown below is a concept drawing of what we will design and build for deployment at our 2 MW site in the Minas Channel. We expect to build and deploy this by the fall of 2025. With the Power Purchase Agreement (PPA) we have, we can bring in over $40M in revenue over 15 years. It will cost less than $10M to build and deploy and about 40% of this will come back in the form of SR&ED payments from the Federal Government. When this is up and running, we will build and deploy many more turbines for the Bay of Fundy and hundreds of turbines in European tidal sites and hundreds more in different parts of the world. See a representation of our 2 MW turbine below as well as a VERY POWERFUL VIDEO with world class expert Ray Hunter as well as interviews with Greg from GRF Structural Engineering and Jeff from Loci Robotics.