GREAT PHYSICS

The Archimedes screw is far more robust than a bladed turbine like those used in the wind industry. Because water is 800 times more dense than air, turbulent water multiplies the stress effects on bladed turbines to many magnitudes. Also, the larger the diameter, the more the problem multiplies because the water flow speed varies throughout the water column. The Jupiter screw turbine presents a solid surface throughout the area of exposure to the flow and, therefore, is completely capable of handling these varying forces and because the whole screw is oriented at a 30 degree angle to the flow, the bearings are far less stressed. Debris, fish nets, rope, weeds and branches roll right on through the screw turbine. Clearly this is not the case with bladed turbines.

ADAPTABILITY

As you can see by some of the drawings below, we are adaptable to any size and orientation. We can go in shallow rivers and even adapt to very deep applications. Some day, we will come up with an effective way to capture the energy in the Gulf Stream which is around 800 meters deep. It will have to be submerged to be hurricane proof. Some interesting issues to solve on this one.

ADVANTAGES OF FLOATING TIDAL, ESPECIALLY JUPITER’S

In an ORE Catapult Technology Assessment Report, assessing the Jupiter technology in 2016, Ray Hunter, a world class expert in tidal energy stated: “Compared with bottom fixed devices, there is growing recognition that moored, buoyant platforms offer potential advantages in power level, cost of station-keeping and ease of deployment and maintenance. Jupiter enjoys these advantages”. Ray is also on the video on the bottom of the Home Page.

This statement proved to be very prophetic. When the FORCE tidal test site opened in 2009, all the test spots were slated for bottom mounted turbines. Now, in 2023, 4 out of 5 of the technologies going in and around the FORCE test site are floating platforms.

In the fall of 2022, Ross Sinclaire got the final vision as to how to deploy Jupiter’s floating technology in the 2 MW site in the Bay of Fundy. Using the 4 screw barge that is shown on the home and technology pages along with some novel new ideas that came to him, he is now quite confident that he can deploy this unit without having any concerns about storm conditions, debris, angle of orientation to the flow, anchoring or power cabling. In many ways, he has been fortunate that he did not have government support or investors willing to fund the build of this floating turbine. He has only been able to dig down and study all the different ideas being tested by those with funding and especially investigate ideas around anchoring and power cabling. He observed that, in the right wind and wave conditions, it is impossible to orient a bladed turbine at the 90 degrees that it should be maintained at and this will lead to huge maintenance problems. He also observed that the power cable technologies being deployed are very questionable because they are fighting force with force and that can be a losing battle out in the ocean. He believes that he finally has figured out a solution that will use the forces involved to assist the process in any weather condition and the Jupiter turbine will not have these issues when it is deployed. To ask more questions around this call Ross at 902-880-8242 and also look at the video at the end of the Technology page.

From grid scale to micro, we are fish friendly. The two turbines shown below have the same flow exposure in square meters to normalize comparison of the radically different shapes.

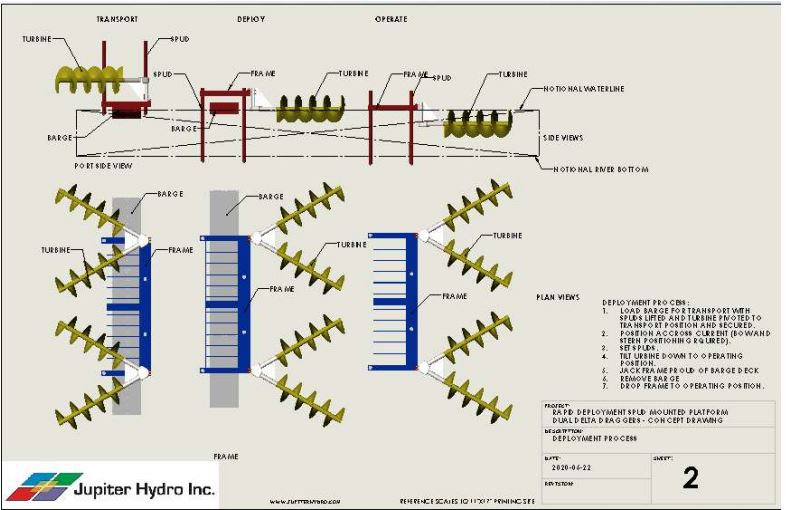

The technology can be deployed in multiple ways, from barge platforms to spud frames to embankment mounting.

Rapidly deployable spud frames